Powering Critical Needs: The 1000kw Backup Generator

In today's hyper-connected and operationally dependent world, power outages are far more than just a minor inconvenience. For many businesses, institutions, and critical infrastructure, a loss of power can mean catastrophic financial losses, compromised safety, or even a complete halt of essential services. Hospitals can't perform life-saving procedures, data centers can't maintain vital information flows, and manufacturing plants face costly downtime. This is where the need for robust, reliable backup power becomes paramount. While smaller generators suffice for residential or small commercial needs, large-scale facilities require serious power, often measured in megawatts. Stepping up to meet these demands is the impressive and essential 1000kw backup generator. This isn't just a luxury; for many, it's a fundamental requirement for continuity, resilience, and safety. Understanding the capabilities and importance of a generator of this size is crucial for anyone responsible for ensuring uninterrupted operations when the grid goes dark. It represents a significant investment, certainly, but one that protects against far greater potential losses and ensures that when every watt counts, you have the power you need, precisely when you need it.

Why a 1000kw Capacity is Often Necessary

Frankly speaking, a 1000kw capacity generator is not a typical residential unit. It's designed to handle massive power loads, making it suitable for a specific set of demanding applications. Think large industrial facilities, major hospitals, airports, large data centers, utility substations, large retail complexes, or even emergency response centers. These locations have extensive power requirements, supporting everything from sophisticated medical equipment and life support systems to vast server farms, heavy machinery, HVAC systems for large buildings, and extensive lighting and security networks. Calculating the exact power need is the first critical step, and for many of these operations, 1000kw (or 1MW) represents the minimum or optimal capacity to ensure that all essential, and often non-essential but important, systems can continue functioning during an outage. Overlooking this calculation can lead to choosing an undersized generator, which simply won't be able to carry the load, resulting in partial or complete system failures anyway. This level of power capacity provides the reassurance that critical operations won't be compromised, maintaining safety protocols, data integrity, and operational workflows even during prolonged grid disruptions. It's about protecting significant assets and ensuring business continuity on a grand scale.

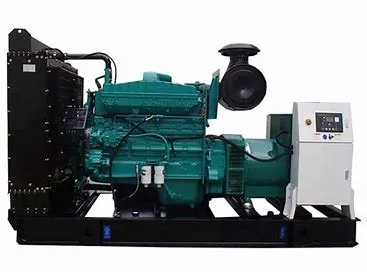

Core Components and Technology Behind High-Capacity Units

Peering under the hood of a 1000kw backup generator reveals sophisticated engineering designed for performance and reliability. At its heart is a powerful engine, typically a large diesel or sometimes a natural gas engine, built for continuous operation under load. This engine drives an alternator (often referred to as the generator end) which converts mechanical energy into electrical energy. Complementing these primary components are several critical subsystems. There's a robust cooling system to prevent overheating during extended runs, a lubrication system for engine health, and a fuel system designed to supply the significant volume of fuel required for this capacity. Modern units also feature advanced digital controllers. These controllers monitor engine parameters, manage power output, interact with the facility's transfer switch, and often provide remote monitoring and diagnostics capabilities. They are essentially the brain of the generator, ensuring it starts automatically when grid power fails and manages the transition seamlessly. The enclosure protecting these components is often sound-attenuated to reduce noise pollution and weather-resistant, ensuring reliable operation regardless of external conditions. Interestingly enough, the sheer scale of these components means installation often requires specialized equipment and expertise, adding another layer of complexity compared to smaller generators.

Understanding Fuel Types: Diesel vs. Natural Gas

When considering a 1000kw backup generator, one of the primary decisions revolves around the fuel source: diesel or natural gas. Both have their distinct advantages and considerations for large-scale applications. Diesel generators are traditionally favored for backup power due to their reliability, durability, and the fact that diesel fuel can be stored on-site, making it readily available even if the natural gas supply is interrupted (though rare). They also tend to start quickly and handle large load changes effectively. However, diesel generators require regular fuel replenishment, on-site fuel storage involves safety and environmental regulations, and their emissions can be higher than natural gas. Natural gas generators, on the other hand, offer a continuous fuel supply via the utility pipeline, eliminating the need for on-site storage tanks and reducing refueling logistics. They also produce lower emissions and tend to be quieter. The main considerations for natural gas are the availability and pressure of the local gas line at the installation site (which must be sufficient for a 1000kw unit) and the potential vulnerability of the gas supply during widespread emergencies like earthquakes or major infrastructure failures. The choice between diesel and natural gas often depends on factors like local fuel availability and cost, environmental regulations, site constraints, and specific operational reliability priorities. Many experts agree that both are viable options for this capacity, but a thorough site assessment and requirement analysis are essential before making a decision.

Critical Applications Reliant on 1000kw Backup Power

To be honest, without robust backup power like that provided by a 1000kw generator, many critical operations would grind to a halt, with potentially severe consequences. Think about a large teaching hospital. A power outage could jeopardize ongoing surgeries, shut down life support equipment in ICUs, disable critical diagnostic imaging machines, and plunge patient rooms into darkness. Data centers are another prime example; even a brief flicker can lead to data corruption, hardware damage, and service interruptions that cost millions per minute for major cloud providers or financial institutions. Manufacturing plants, especially those with continuous processes or sensitive equipment, rely on this power to prevent costly production stoppages and damage to machinery or raw materials. Airports need uninterrupted power for air traffic control, runway lighting, security systems, and passenger services. Even large office buildings might require 1000kw to keep essential functions like elevators, emergency lighting, security, and critical servers operational during an extended outage. The scale of a 1000kw unit signifies the magnitude of the operations it is designed to protect, highlighting that for these applications, backup power isn't a contingency plan; it's a fundamental operational necessity integrated into the infrastructure from the ground up. This level of power capability ensures resilience against unforeseen disruptions, safeguarding both assets and lives.

Installation Considerations for Large Generators

Installing a generator of this size, a 1000kw backup generator, is a complex project that requires careful planning and execution, going far beyond simply finding a flat spot. Site selection is critical; the location must be able to support the generator's significant weight and provide adequate space for maintenance access. Noise levels are a major factor, necessitating careful consideration of proximity to occupied buildings and potential use of sound attenuation measures. Proper ventilation is essential for engine cooling and exhaust dispersal; the sheer volume of exhaust from a 1000kw unit requires a well-designed exhaust system. Fuel storage (for diesel) or gas line connection (for natural gas) must meet strict safety and regulatory standards. The electrical connection to the facility's transfer switch and main distribution panel must be professionally engineered and installed to handle the full load. Furthermore, local building codes, environmental regulations (especially regarding emissions and fuel storage), and zoning laws must be thoroughly researched and complied with. Often, pouring a custom concrete pad is necessary to provide a stable, vibration-resistant base. Frankly speaking, this is not a DIY project; it requires experienced engineers, electricians, and contractors familiar with large-scale power systems to ensure safety, compliance, and reliable operation.

Maintenance is Key to Reliability

Having a 1000kw backup generator installed provides peace of mind, but that peace is only as reliable as the generator's maintenance program. These aren't set-it-and-forget-it machines. Regular, preventative maintenance is absolutely critical to ensuring that the generator starts and runs correctly when called upon during an emergency. A typical maintenance schedule includes routine inspections, oil and filter changes, coolant checks, fuel system checks, battery testing (the most common failure point!), and load bank testing. Load bank testing is particularly important for large generators; it involves connecting the generator to a device that simulates its full load capacity, allowing technicians to verify that it can perform under stress and helping to identify potential issues before a real outage occurs. Keeping detailed maintenance logs is vital for tracking service history and anticipating future needs. Neglecting maintenance can lead to failures during critical moments, costly repairs, and a significantly shortened lifespan for the equipment. Many facilities opt for professional maintenance contracts with experienced providers who specialize in large industrial generators, offering scheduled service and emergency support. In my experience, investing in regular, thorough maintenance is one of the most cost-effective decisions you can make to protect your investment and ensure operational continuity.

Choosing the Right Generator: Factors to Consider

Selecting the appropriate 1000kw backup generator involves more than just specifying the power output. Several factors must be carefully evaluated to ensure the unit meets the specific needs and constraints of the application and site. Beyond the obvious capacity requirement and fuel type discussed earlier, consider the intended run time – will it need to run for hours or days? This impacts fuel storage needs and engine duty rating. Noise restrictions in the area might necessitate higher levels of sound attenuation. The type of load the generator will power is also important; will it be handling sensitive electronics, large motors with high starting currents, or a mix? This influences the required voltage regulation and transient response characteristics of the alternator. Environmental factors like extreme temperatures, humidity, or altitude can affect performance and require specific modifications or considerations. Furthermore, compliance with local, state, and federal regulations regarding emissions, noise, and fuel storage is non-negotiable. It's worth noting that the generator's control system capabilities – such as remote monitoring, paralleling capabilities (if multiple generators are used), and integration with building management systems – should also align with operational needs. Consulting with power generation experts is highly recommended to navigate these complex factors and make an informed decision, ensuring you get a solution tailored to your exact requirements.

The Investment and Long-Term Value

Undeniably, acquiring and installing a 1000kw backup generator represents a substantial upfront investment. The cost includes the generator unit itself, transportation, site preparation, installation labor, electrical work, fuel system setup, and potentially sound attenuation or enclosure costs. However, it's crucial to view this cost in the context of the long-term value and return on investment (ROI) it provides. For businesses and critical facilities, the cost of an outage, especially an extended one, can be astronomical. This includes lost revenue, damaged goods or equipment, data loss, safety hazards, decreased productivity, and reputational damage. Compared to these potential losses, the investment in reliable backup power often pays for itself by preventing just one or two significant disruptions over its lifespan. Furthermore, having robust backup power can sometimes lead to lower insurance premiums or satisfy regulatory requirements, providing additional financial benefits. When evaluating the investment, consider the total cost of ownership, which includes fuel costs, maintenance expenses over the unit's life, and potential future upgrades. A well-maintained 1000kw unit can provide reliable backup power for decades, making it a foundational element of operational resilience and a sound financial decision when the potential costs of failure are high. Have you ever wondered about the true cost of *not* having adequate backup power?

Ensuring Operational Resilience and Safety

Ultimately, the primary goal of investing in a 1000kw backup generator is to ensure operational resilience and safety. For facilities where power is integral to safety systems (like hospitals, emergency centers, or manufacturing plants with hazardous processes), uninterrupted power isn't just convenient; it's a matter of life and death or preventing major accidents. Resilience means the ability to withstand and recover from disruptions. With a reliable backup power system, operations can continue seamlessly, minimizing downtime and maintaining productivity. This proactive approach prevents the chaos and scrambling that often occurs during unexpected outages. Beyond immediate continuity, reliable backup power enhances long-term security and preparedness. It ensures communication systems stay online, security measures remain active, and essential services continue to be delivered to the community or customers. It provides the peace of mind that comes from knowing you are prepared for grid failures, whether caused by severe weather, equipment malfunctions, or other unforeseen events. Building resilience into your infrastructure with a powerful and dependable backup generator is a strategic move that protects your operations, your assets, and the safety of everyone who relies on your facility.

How Our Solutions Address Large-Scale Power Needs

Understanding the complexities and critical nature of deploying a 1000kw backup generator for your facility is just the beginning. The challenge lies in translating those requirements into a tailored, reliable, and compliant power generation solution. This is where our expertise comes into play. Our company specializes in providing comprehensive power generation solutions for large-scale and critical applications. We don't just sell generators; we partner with you from the initial power assessment and system design phase, helping you accurately determine your load requirements and select the optimal generator size and fuel type – including expert guidance on 1000kw systems. We assist with site evaluation, ensuring compliance with all relevant regulations and codes, and manage the complex logistics and installation process. Our services extend beyond installation to include commissioning, preventative maintenance programs designed to maximize uptime and lifespan, and emergency repair services. We understand the unique challenges of large commercial generator requirements and industrial standby generator needs. Our goal is to provide a seamless, end-to-end solution that ensures your critical operations remain powered, regardless of grid conditions, allowing you to focus on your core mission with confidence in your power infrastructure.

Next Steps Towards Securing Your Power Future

Securing your operations with a reliable 1000kw backup generator is a significant undertaking, but one that provides invaluable protection against the unpredictability of power outages. If your facility has substantial power needs and critical operations that cannot tolerate downtime, exploring a high-capacity backup power solution is a necessary step. Your next action should involve a thorough assessment of your current and future power requirements. Consider not only your essential loads but also any systems that would benefit from uninterrupted power to maintain full functionality during an outage. Identify potential installation locations at your site and research local regulations concerning generators. The most important step is to consult with experienced professionals in the field of large-scale power generation. They can provide expert analysis of your needs, recommend the most suitable equipment and configurations, and guide you through the complex process of selection, installation, and ongoing maintenance. Don't wait for the next power outage to highlight the gaps in your preparedness. Take proactive measures today to ensure your critical operations are safeguarded by a robust and reliable backup power system. Investing in power resilience is investing in the future stability and safety of your facility.

For more detailed information, please visit our official website: 1000kw backup generator

winning power

winning power